Forming technology

Our expertise in sheet metal forming allows us to produce complex components with maximum efficiency and quality. We pay attention to precision and the use of innovative processes.

Forming technology

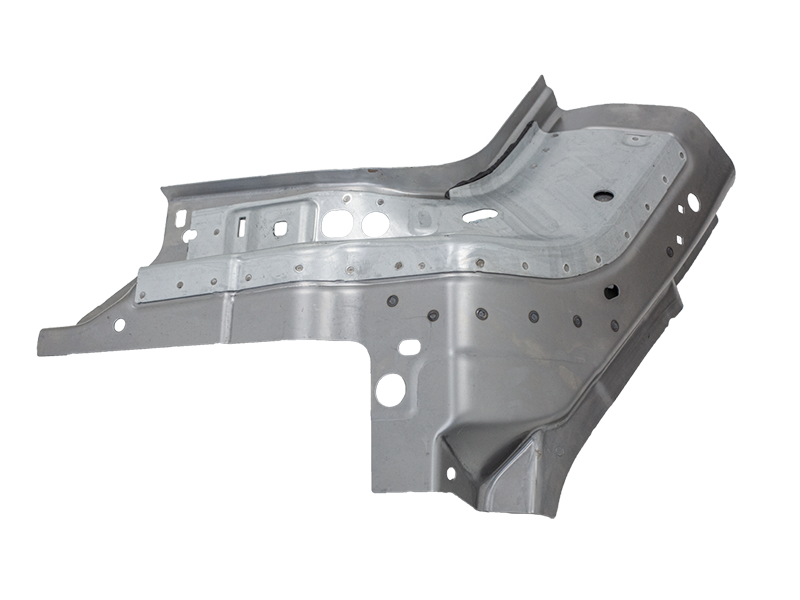

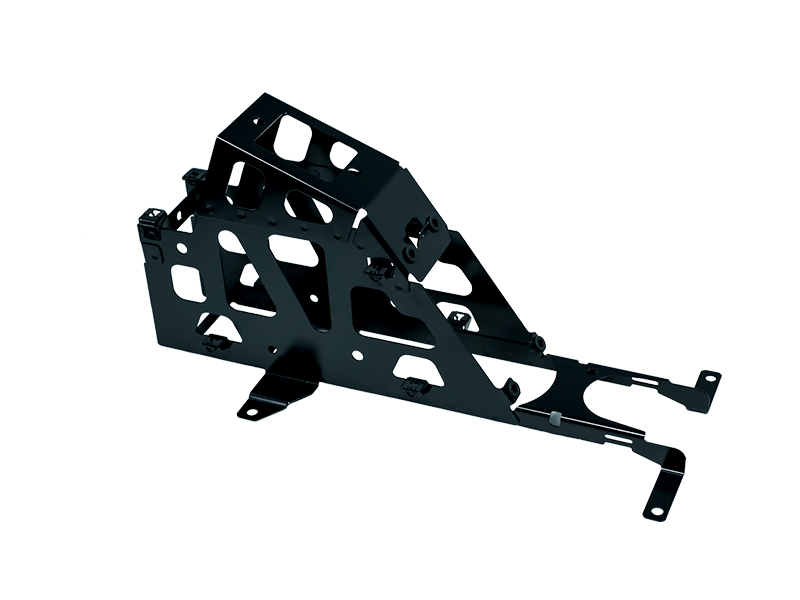

In forming technology, we consider the entire process chain from the coil to the finished product. Our engineering department develops the right process for manufacturing the products and oversees its implementation from toolmaking to series production. We work with progressive and transfer technology as well as combinations thereof. In our press shops, we use state-of-the-art linkdrive and servo transfer presses in conjunction with coil feed. We can draw on press forces from 2,000 to 20,000 kN. We process sheet thicknesses between 0.5 and 4 mm. Our machines have table lengths of up to 6,000 mm. Our range of components covers everything from the simplest stamped and drawn parts to complex component geometries. We process steel and aluminum materials in all strength classes equally reliably and to a high standard.

Technical details

Pressing forces

from 5,000 to 20,000 kN

Table sizes & sheet thicknesses

We process sheet thicknesses between 0.5 and 4 mm. We have table sizes of up to 6,000 mm at our disposal.

Materials

Steel and aluminum

Press park

We have 18 automatic presses in the group (including state-of-the-art progressive and serving presses, a mini-tandem line)

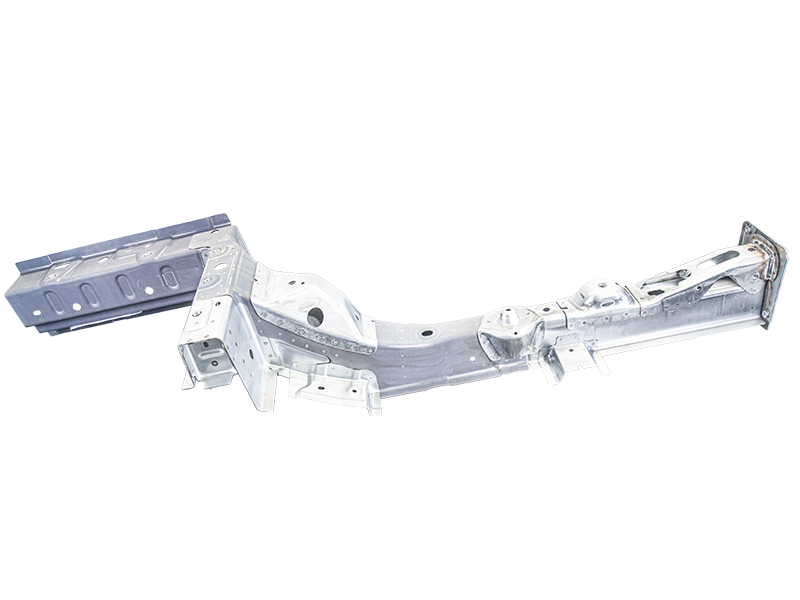

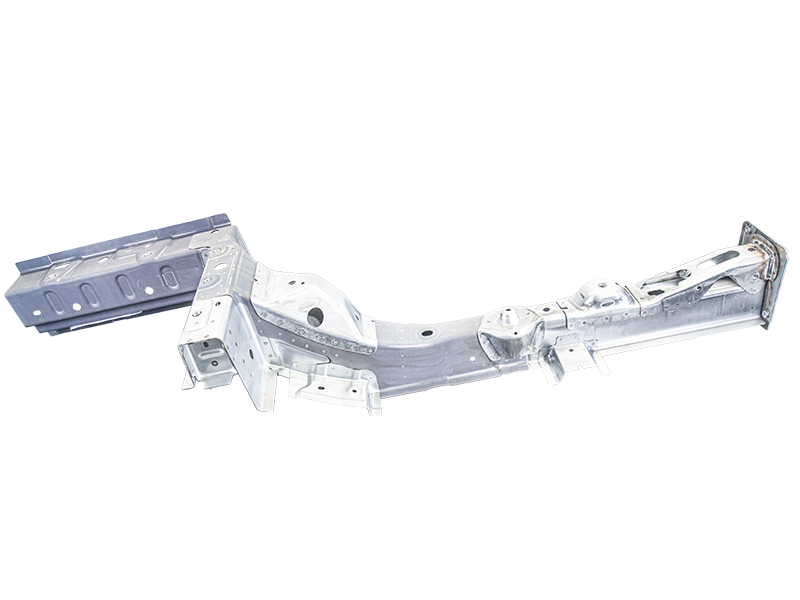

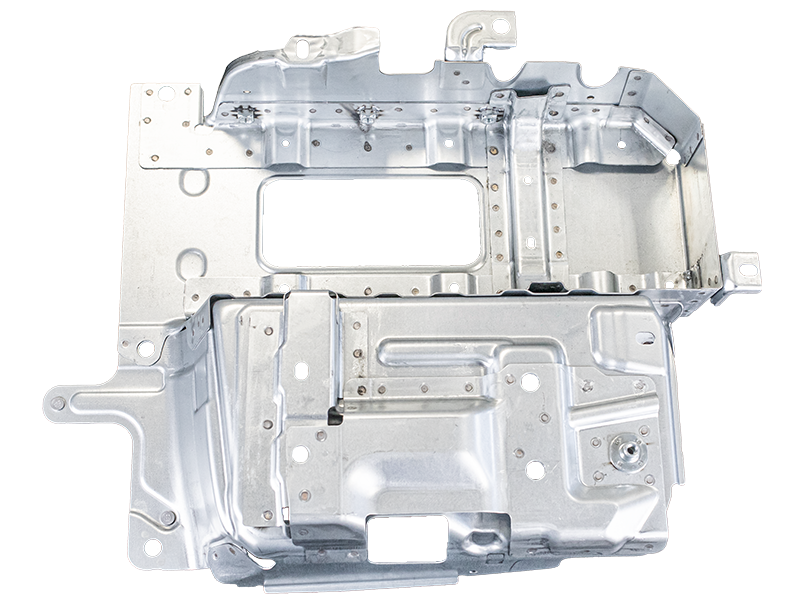

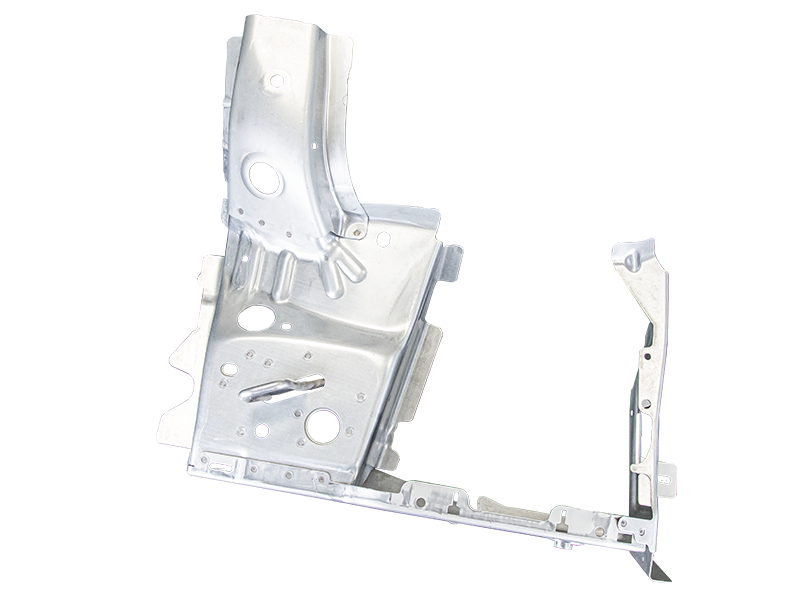

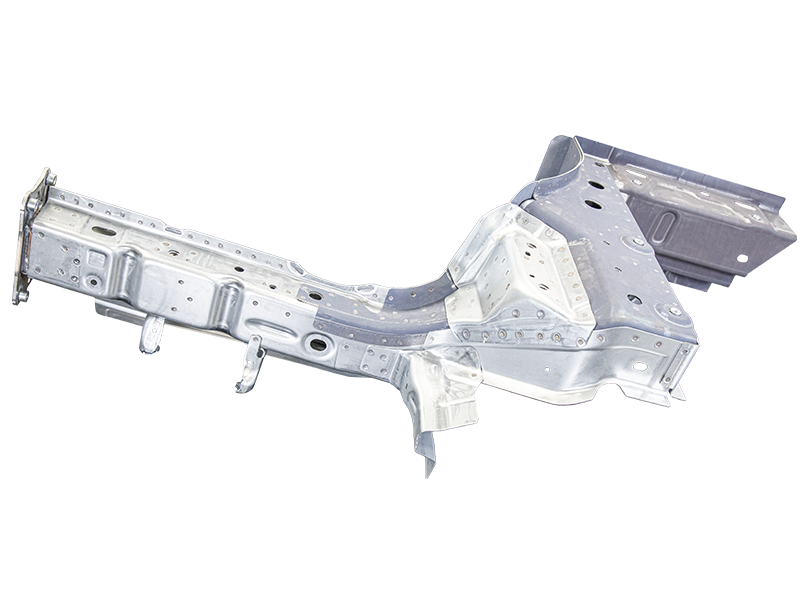

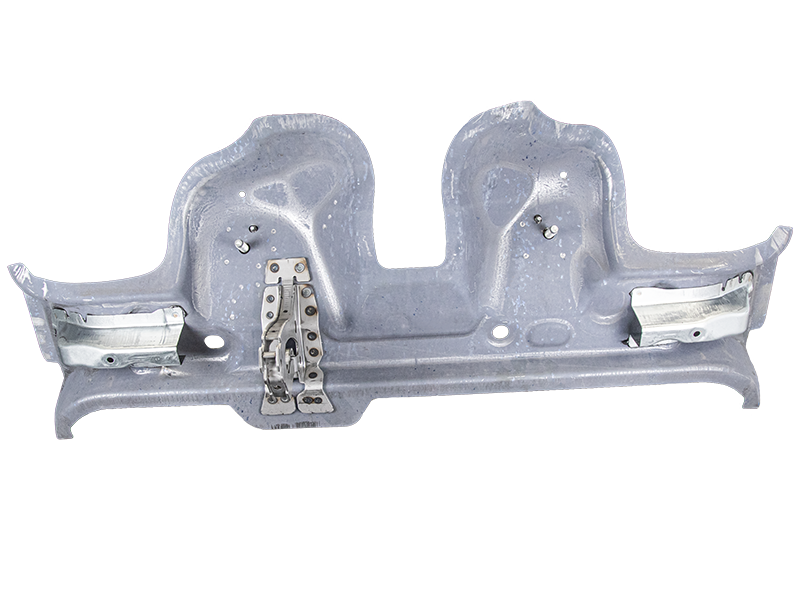

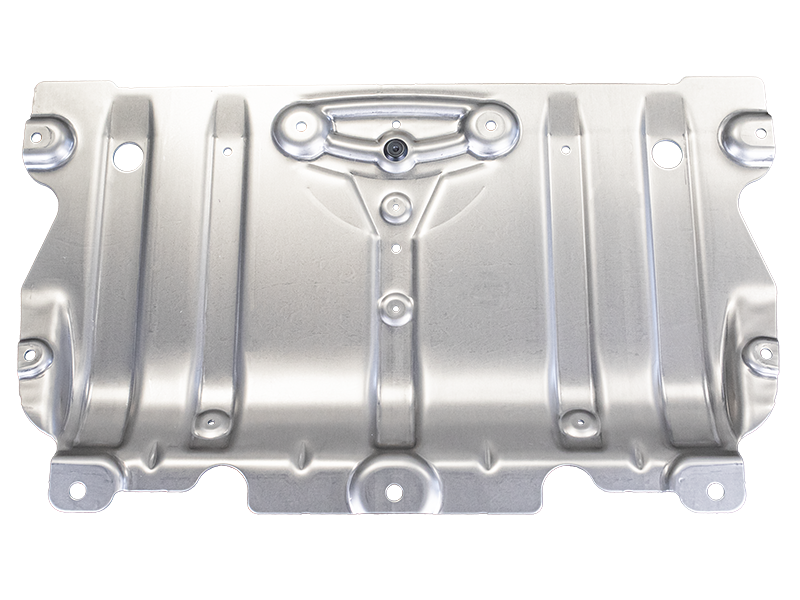

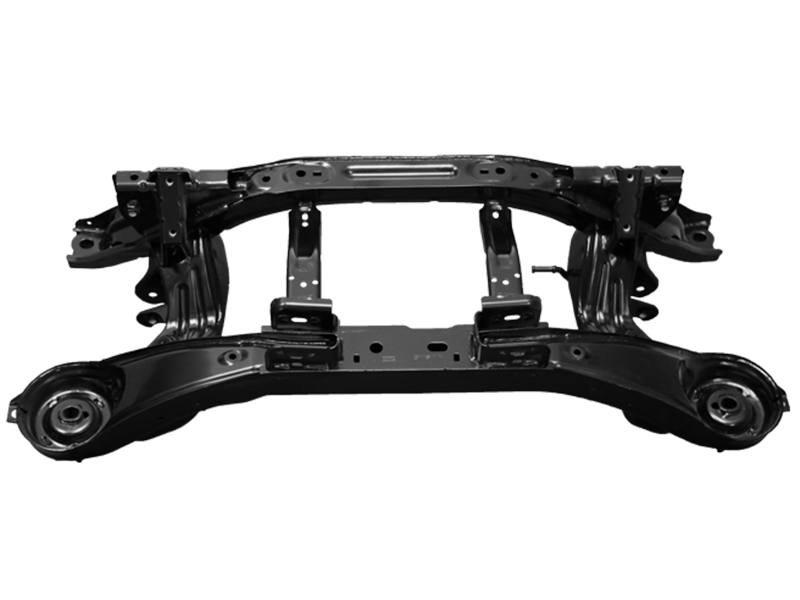

Product examples

Have you got any questions?

Do you have specific questions or innovative ideas that you would like to share with us? We invite you to become part of our journey. Make an appointment and our experienced team will advise you in detail – whether in person or digitally. Shape ‘tomorrow’ with us – contact us today!

Phone

+49 (0) 2739 8957 - 0

info@meleghyautomotive.de

More technologies

Forming technologies

We bring sheet metal into shape

Joining technologies

We connect structures

Coating technologies

We coat sustainably